Co-Axial Blade Probe California: Precision Measurement Solutions

- Semi Probes Inc

- Jul 30, 2025

- 4 min read

In the fast-evolving world of precision engineering, the co-axial blade probe stands out as a critical tool for industries requiring exact measurements. Particularly in California, a hub for cutting-edge technology and manufacturing, co-axial blade probes are driving advancements in sectors like aerospace, medical device production, and automotive engineering.

These specialized devices offer unmatched accuracy and versatility, making them essential for quality control and metrology applications. This article explores the significance of co-axial blade probes, their functionality, applications in California’s industries, and why they are a game-changer for precision measurement.

What is a Co-Axial Blade Probe?

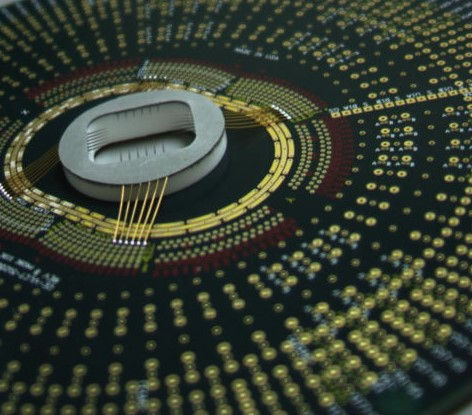

A co-axial blade probe is a sophisticated measuring instrument designed to deliver highly accurate dimensional measurements. Unlike traditional probes, which often rely on separate components for contact and sensing, the co-axial blade probe integrates a blade and stylus aligned along the same axis. This unique design enhances stability and precision, ensuring that measurements are consistent even in challenging environments.

The probe’s blade makes contact with the surface being measured, while an internal sensor detects the deflection and converts it into precise data. This data is then transmitted to a measuring device, such as a coordinate measuring machine (CMM), for analysis. The co-axial design minimizes errors caused by misalignment, making it ideal for applications where tight tolerances are non-negotiable.

In California, where industries like aerospace and medical device manufacturing demand pinpoint accuracy, co-axial blade probes have become indispensable. Their ability to measure complex geometries and delicate components without compromising precision sets them apart from other tools. The probe’s durability also ensures it can withstand repeated use in high-throughput production settings, which is critical for California’s fast-paced manufacturing sector.

How Co-Axial Blade Probes Work

The functionality of a co-axial blade probe is both elegant and efficient. The probe consists of a blade assembly, a stylus, and an internal sensor mechanism, all aligned along a single axis. When the blade comes into contact with a surface, it deflects slightly. This deflection is detected by the sensor, which converts the movement into electrical signals.

These signals are then transmitted to a connected measuring instrument, such as a CMM, which processes the data to produce precise measurements. The co-axial alignment ensures that the blade and stylus move in perfect harmony, reducing errors that might occur with less integrated designs.

The data collected by the probe is analyzed and displayed in a format that provides actionable insights, such as dimensional data or surface profiles. Modern co-axial blade probes often integrate with advanced software, allowing for real-time analysis and visualization. This capability is particularly valuable in California’s tech-driven industries, where manufacturers need immediate feedback to maintain quality standards. The combination of precision engineering and digital integration makes co-axial blade probes a powerful tool for ensuring product reliability and consistency.

Advantages of Co-Axial Blade Probes

The co-axial blade probe’s design offers several key advantages that make it a preferred choice for California’s industries. First and foremost is its high precision. The co-axial alignment of the blade and stylus ensures that measurements are accurate to within micrometers, which is essential for industries with strict quality requirements. This precision reduces the risk of defects and costly rework, saving manufacturers time and money.

Another significant advantage is the probe’s versatility. Co-axial blade probes can measure a wide range of surfaces, from flat planes to complex curves, making them suitable for diverse applications. This flexibility is particularly valuable in California, where industries often work with intricate and varied components. The probes’ durability also ensures they can handle the demands of high-volume production without losing accuracy over time.

Additionally, co-axial blade probes are compatible with advanced measurement systems, allowing for seamless integration into automated production lines. In California’s tech-forward manufacturing environment, this compatibility enhances efficiency and supports data-driven decision-making. The probes’ ability to interface with software for real-time analysis further streamlines quality control processes, enabling manufacturers to identify and address issues quickly.

Why California Leads in Co-Axial Blade Probe Innovation

California’s position as a global leader in technology and manufacturing has fostered an environment where tools like co-axial blade probes thrive. The state’s concentration of engineering talent, research institutions, and innovative companies drives continuous improvements in probe design and functionality.

Companies like Semi-Probes Inc., based in Santa Clara, are at the forefront of developing advanced co-axial blade probes tailored to the needs of California’s industries. These innovations ensure that probes remain cutting-edge, meeting the evolving demands of precision measurement.

The state’s emphasis on sustainability and efficiency also aligns with the benefits of co-axial blade probes. By reducing errors and improving quality control, these probes help manufacturers minimize waste and optimize resources. This is particularly important in industries like aerospace and automotive, where sustainability is becoming a key focus. California’s commitment to technological advancement and environmental responsibility makes it an ideal hub for the adoption and development of co-axial blade probes.

FAQs

What makes co-axial blade probes different from traditional probes?

Co-axial blade probes differ from traditional probes due to their integrated design, where the blade and stylus are aligned along the same axis. This configuration enhances stability and accuracy, reducing errors caused by misalignment and making them ideal for high-precision applications.

Which industries in California use co-axial blade probes?

Co-axial blade probes are widely used in California’s aerospace, medical device, automotive, and general metrology sectors. They are critical for measuring components in aircraft, medical devices like pacemakers, automotive parts, and experimental prototypes.

How do co-axial blade probes improve quality control?

These probes improve quality control by providing highly accurate dimensional measurements and surface profiles. Their precision ensures that components meet strict tolerances, reducing defects and ensuring product reliability in industries like aerospace and medical device manufacturing.

Are co-axial blade probes compatible with modern manufacturing systems?

Yes, co-axial blade probes are designed to integrate with advanced measurement systems like CMMs and can interface with software for real-time data analysis. This compatibility makes them ideal for automated production lines in California’s tech-driven industries.

Where can I find co-axial blade probes in California?

Companies like Semi-Probes Inc. in Santa Clara specialize in co-axial blade probes. California’s tech hubs, including Silicon Valley and San Diego, are home to suppliers and manufacturers offering these precision tools.

Comments